We are hiring. General Tool Company’s strongest competitive advantage is our people.

Aerospace work requires the highest level of technical competence and is a focus for all levels of our organization. Aerospace hardware is one of our core competencies.

Air transport has truly made our world both smaller and larger at the same time. We can reach overseas destinations in mere hours, enabling us to connect on a global basis. GTC’s competence in aerospace work serves customers striving to stay on top of their marketplace.

New commercial airline and military jet engine programs remain strong, regardless of the ups and downs in aircraft production. The development of new engine designs is moving forward with a renewed emphasis on delivery of fully tested models that expand the limits of jet engine performance. GTC excels at producing prototypes and “first articles” for validating processes, verifying production results and establishing a baseline for quality control procedures. Our competence in this area helps reduce production timelines and increase first-pass yield on development programs. Likewise, we are experts at providing the production hardware such as workholding fixtures, transport devices and locating systems.

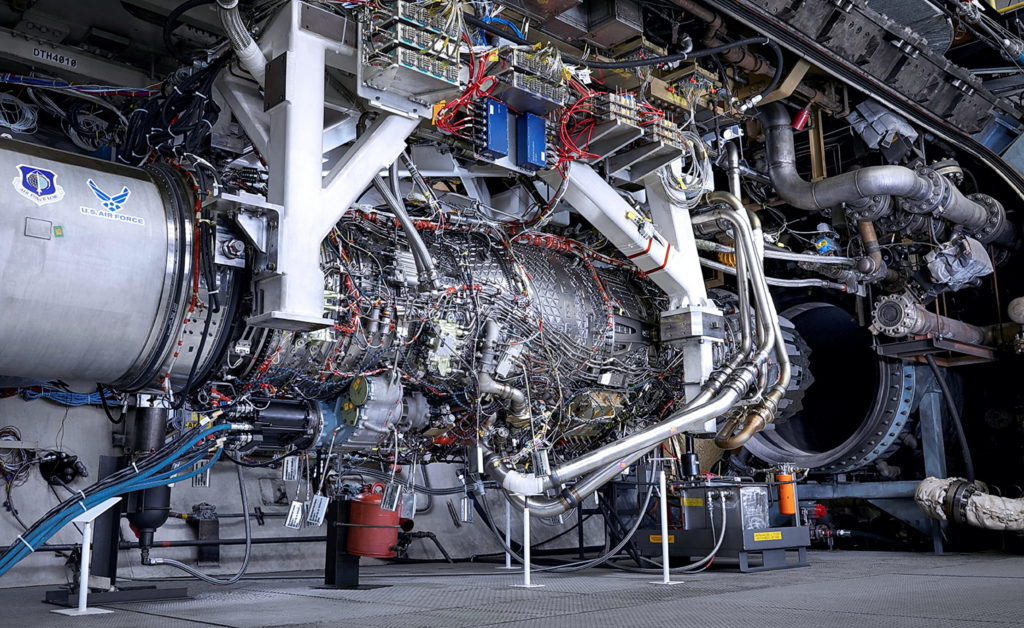

Ever since General Electric began to manufacture turbine engines in Cincinnati in 1948, GTC has supplied hardware systems to support he development of new commercial and military engines. We fabricate, machine and assemble finished engine test stands on which jet engines are operated at conditions that simulate normal and extreme flight conditions. For this work, GTC employs its special welding skills that are audited for compliance with applicable certification programs. Critical welds are X-rayed to ensure there are no internal defects. Other non-destructive tests are conducted to certify that finished weldments meet aerospace quality requirements.

Split cases, rings and engine shafts are some of the most prominent components of every jet engine, and are frequently produced at GTC. These Inconel or titanium parts must meet the highest quality requirements. The parts cross many of our work centers, especially the numerous five-axis machines of various configurations or one of our many VTLs. Ring-shaped components often can be completed in one or two setups on machines capable of both milling and turning operations. This approach saves time and reduces the risk of error during repositioning.

GTC has been manufacturing ducts, fans and other structures made of carbon fiber reinforced polymers (CFRP) for more than 20 years. Because commercial technology for forming, machining and trimming CFRP components was not entirely satisfactory, GTC invented its own tooling and processes to machine these parts to exacting tolerances. Our expertise in this area helps customers evaluate prototypes in the development phase, often through multiple iterations, to arrive at a final design that can be produced more practically and more economically.

General Tool Company has been supporting space projects since the Space Shuttle program in the 1980’s. We have made space hardware for rockets, missiles and satellites. Major components such as fuel tanks have relied on GTC’s patented processes for joining subcomponents with friction stir welding (FSW). Most recently, this proprietary technology has contributed to the latest generation of SpaceX launch vehicles, which pioneered the use of recoverable and reusable boosters.