We are hiring. General Tool Company’s strongest competitive advantage is our people.

General Tool Company Expands Workforce and Advanced Manufacturing Capabilities

November 29 2018, by Pete Borden

General Tool Company of Reading, OH continues to invest in people and technology as our customers’ needs expand. We’ve received new long term contracts for Aircraft Carriers, Destroyers, Radar and F-35 components and systems this year that require more skilled workers and new machine tools to meet stringent quality requirements for these programs. We’re proud that our workforce has grown by 20% in the last year.

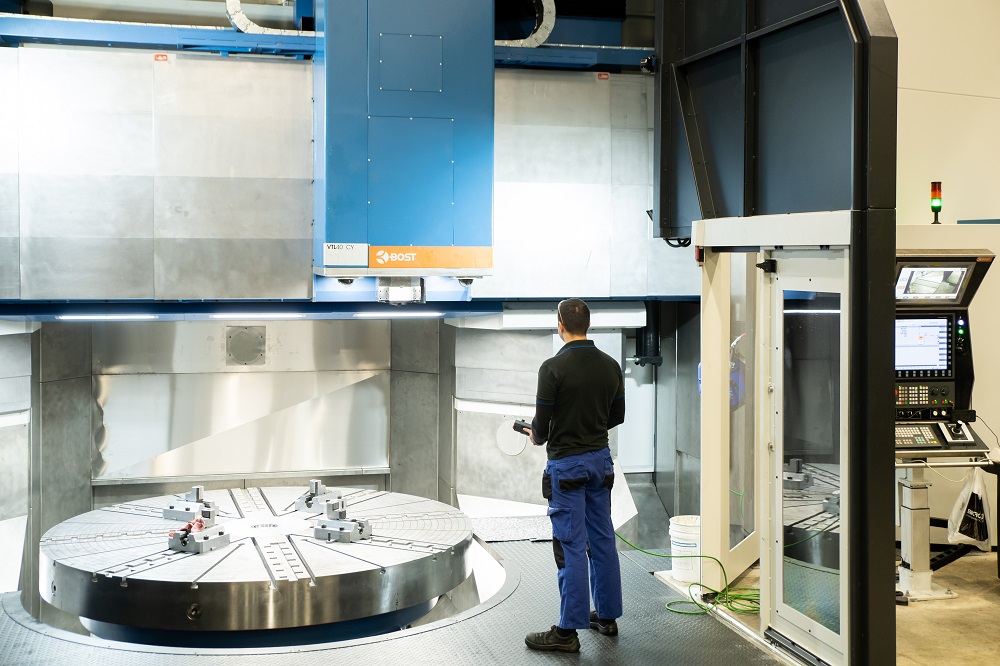

We’ve also invested in new four new 5 axis machine tools from Parpas Group and Bost Machine. The Bost is our largest machine ever. It’s 3 meter chuck has a Y axis that expands the cutting diameter to 4 meters. The vertical capacity is 2 meters. A head changer adds more capabilities with a full contouring head with a 50 HP rating which is ideal for machining high temperature alloy aerospace parts in one setup.

Greg Kramer, Chief Technology Officer, commented that “these machines are adding new capabilities to our shop which very few factories in the United States can offer; but, more importantly, they provide our customers more solutions by performing more operations, more efficiently, on one machine. General Tool Company of Reading, Ohio continues to invest in both people and technology to meet the evolving needs of its defense and aerospace customers. In 2023, the company secured new long-term contracts for aircraft carriers, destroyers, radar systems, and F-35 components, driving the need for additional skilled workers and advanced machine tools to meet stringent quality requirements. Over the past year, the workforce has grown by 20%, reflecting GTC’s commitment to talent development and operational excellence.

To support these programs, GTC has added four new 5-axis machine tools from Parpas Group and Bost Machine, including the company’s largest machine ever. The Bost machine features a 3-meter chuck, a Y-axis that expands the cutting diameter to 4 meters, and a 2-meter vertical capacity. Its full-contouring head with a 50 HP rating enables precise machining of high-temperature aerospace alloys in a single setup, reducing cycle times while maintaining the highest quality standards.

Greg Kramer, Chief Technology Officer, commented:

“These machines are adding new capabilities to our shop that very few factories in the United States can offer. More importantly, they provide our customers with more solutions by performing multiple operations more efficiently on a single machine.”

This investment underscores GTC’s ongoing commitment to providing advanced manufacturing solutions, supporting critical aerospace and defense programs, and maintaining a workforce capable of delivering precision and reliability at scale.